SATS x WasteMaster: Turning food waste into value

Waste doesn’t have to be wasted. This principle drives SATS’ adoption of the WasteMaster technology at the In-Flight Catering Centre (ICC)1, which has been in operation since November 2023.

.jpg?sfvrsn=2749a93d_0)

The WasteMaster deployed at ICC1

The science behind the technology

The WasteMaster, developed by Green Eco Technologies in Australia and operated by Life Lab Resources in Singapore, is a revolutionary food waste processing system that converts organic waste into useful products, such as fertiliser, fish feed, or energy.

SATS operates a one-tonne WasteMaster machine at ICC1, which employs an intelligent system that does not require 24/7 monitoring.

Organic waste from the kitchen and certain inbound flights is put into the machine and processed using a proprietary reactive oxygen technology—which basically means that the system does not require water, heat, bacteria, or chemicals.

Instead, the system utilises air to evaporate water and speed up the breakdown of organic material from the waste. This procedure removes harmful pathogens while preserving the nutritional quality of the food waste, thereby producing substrates rich in nutrients.

Repurposing organic waste

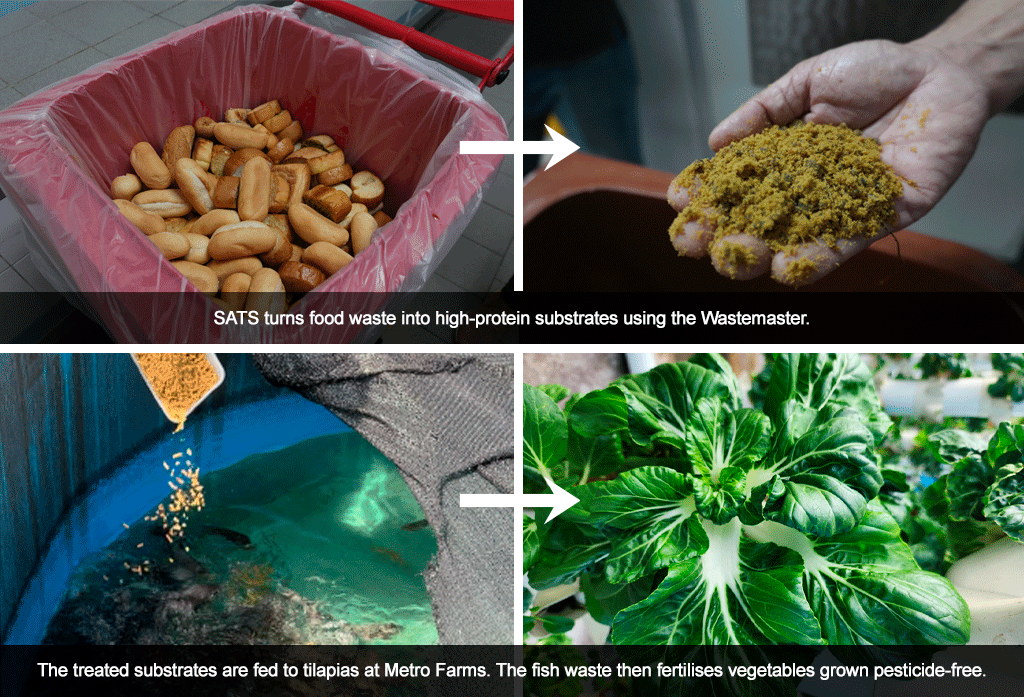

A snapshot of how food waste is processed to become substrates, and eventually used as fish feed

The magic behind the WasteMaster does not end after producing the substrates. Following the processing stage, the substrates undergo additional treatment at Life Lab’s Bio-Refinery Plant.

Acknowledging the excellent protein content of the substrates, SATS and Life Lab teamed up with Metro Farms to explore potential applications in Singapore’s farming industry.

The treated substrates are used as fish feed to grow tilapias at Metro Farms. The waste nutrients from the fish are then used as fertilisers for growing vegetables.

This collaboration has produced encouraging outcomes thus far, with the Singapore Food Agency verifying that vegetables produced through this process are both nutritious and free from pesticides.

Pesticide-free vegetables are grown at Metro Farms

“It’s a closed-loop system that not only benefits the environment but also supports Singapore’s 30-by-30 goal of strengthening local food supply resilience,” Yen Ling, Head of ESG Accounting & Regulatory Compliance at SATS, says.

Reducing carbon emissions

Since its deployment in November 2023, the WasteMaster has processed more than 60 tonnes of organic waste from the SATS’ kitchen and incoming flights. This on-site processing has redirected waste away from incineration, avoiding about 41 tonnes of carbon dioxide emissions.

The WasteMaster also greatly decreases the volume of waste, leading to an 80% reduction in weight, resulting in minimal trips needed to transport substrates from ICC1 to Life Lab’s Bio-Refinery Plant.

Transitions in deployment

As Asia’s leading food solutions provider, SATS is dedicated to tackling the issue of food waste. Introducing the WasteMaster is a move towards this direction.

“The WasteMaster was a natural choice for us,” explains Yen Ling. “It perfectly aligns with our goal of optimising food waste and promoting circularity.” By processing food waste on-site, SATS is not only diverting waste from incineration but also converting it into a valuable resource.

Kenneth Loh, AVP for Catering Technical Services at ICC1, mentions that deploying the WasteMaster into current operations was simple. “We already had a system in place for collecting and weighing food waste, making the transition seamless. The focus then was just fine-tuning our processes rather than overhauling them,” he explains.

Nevertheless, there’s still room for improvement. Kenneth admits that there’s still an opportunity to boost the machine’s capacity to process more waste while also guaranteeing its economic viability in the future.

Looking ahead

At the moment, SATS wants to make the most of the technology and understand its capabilities before scaling up to new sites within Singapore or internationally. “Our immediate priority is to ensure the WasteMaster meets its contracted capacity and output before considering the potential to scale and deploy in other locations,” explains Yen Ling.

There’s also an opportunity for SATS to reintroduce the locally grown vegetables from Metro Farms into its catering operations. If this happens, it would be an ideal illustration of a closed-loop system, wherein the waste from one part of the business is repurposed to support another.

Teams from SATS and Life Lab on a visit to Metro Farms

The core of this initiative revolves around a simple yet potent idea: waste doesn’t have to go to waste. Not only are we reducing waste, but we are also creating something useful out of it. While the WasteMaster may only be a single piece in the bigger picture, it definitely plays a vital role.